Old Man Musings

Much of the history of lighting is written in truss. Today everything to do with truss seems to be standardized, but when I started in the 70’s every lighting vendor seemingly built their own models. Nowadays some companies make their own copies, but the dimensions and shape of these seem to have become universal.

Truss was always changing to adapt to changes in lighting. So just like an archeologist studying the artifacts of a vanished civilization, you can see the history of lighting reflected by truss. Like all histories, it wasn’t always pretty. I’ve seen trusses welded by junkies, box truss collapse on itself, and some near death truss accidents caused by bad technicians. With some 40 years spent working with everything from hanging lights with baling wire on Bamboo truss in Taiwan to hanging lights from 60” triangle truss meant for highway overpasses in Singapore, I think my career may have spanned more truss types, than any one span of truss.

I was an audio guy when See Factor hired me in 1982, but it’s safe to say they converted me into a lighting guy. And with that I learned a little about truss and the different types. These musings are based solely on my experience since becoming a touring lighting guy, and are not meant to be a definitive history of truss.

See Factor had their own Pre Rig Truss design dating back to the mid 70’s, several years before I was hired. They were 8’ long and could stand on end in a truck. But bolting them together daily was amongst the hardest things I or any stagehand ever worked on. The truss did not have endplates with bolt holes that lined up like today’s standard truss. They had plates on the sides with three holes in each. It was impossible to make these holes line up without a drift pin and a mallet. Sawzalls were often a necessary tool for load out.

The old See Factor shop was built from an old factory with an uneven concrete floor. Bob never had it leveled, so the road crews had to bolt trusses together on this floor before every tour. If we couldn’t get the three bolt holes to line up on one part of the floor, you simply pushed the whole truss section 20’ in another direction until you got lucky. Sometime the bolt holes didn’t line up at all, so we had to swop sections of truss around until they lined up. If we could line up the holes on that potholed floor, logic dictated we could align them on a flat stage. Sadly, this assumption was not always correct.

Bob See never threw anything away. When I worked for him he had a whole studio filled with old unused gear. This included the steel triangle truss sections from his original tours with bands like Deep Purple in the 70’s. It took four techs to lift a single 10’ section of this truss. I imagine Bob didn’t have structural engineers approve his designs back then. I was told they would test out these truss designs in the parking lot by seeing how many old engine blocks they could rig to a truss section before it snapped. Rumors said they settled on six.

See Factor also had tons of folding truss. The type where you have two sides of truss that hinged together, but can be opened up into a triangular shape, held in position with spreader bars. These spreader bars were just square stock aluminum with half couplers welded on the end. In 1983 I loaded a truck to go from our NY office to Oregon to start a Talking Heads tour leg. A week later I was on a plane across country when I woke up in a sweat, remembering that I forgot to put the spreader bars in the truck and the next morning I would have five 60’ trusses that I couldn’t assemble. Fortunately I had a layover in St Louis and was able to call the shop and have them ‘counter to counter’ two hundred pounds of metal.

Besides standard lengths of 12 and 20” truss, some lighting vendors had ideas they thought were superior years ago. Obie’s Lighting and Morpheus both designed truss that was open ended on the bottom. It made life easier to focus pars, but the downside was all of these trusses had to land on dollies and pin together for travel. It was OK, but limited. Morpheus built their early truss from square stock as opposed to rounded aluminum. The advantage of this was their whole system could be put together without any C-clamps on conventional fixtures or lining up a truss of movers perfectly. Gravity held lights in place. Instead of clamps they had open ended adaptors that were U-shaped with aircraft pins attached to fixtures. It was fast, but they had to make custom hangers for almost every type of moving light.

Obie’s Lighting took things a step further in the 80’s when they decided it would be a good idea to build dimmers into the truss. They could just run feeder cable up on the truss and save on all the multicables. This seemed like a great concept and may have worked well when they were new. They used LMI dimmers, which often required a subtle kick to be kept working. Hard to kick a dimmer in a truss. That is unless you had your dimmer guy live in the truss for the whole show to turn off the dimmers that would latch themselves on. By 1995 these things were in bad shape, yet they rented them out to us for a Lenny Kravitz tour. We had a bunch of VL5 fixtures hanging in the rig that were fed AC by these dimmers. Eventually the tour was paying for Varilites that couldn’t be powered up because the Obie’s system was just not functionable. I remember the electrician almost being in tears telling us he could not help us, there were no more spare parts, we were just boned.

At some point companies referred to their truss types by a letter. The first time I was in the Showlites shop and someone asked me to go grab and label 40’ of “D-type” truss I was confused, until someone yelled out “20” box truss”. Christie Lites has the most interesting selection of their own truss. They labeled their inventory with letters A-G. A-type truss was 12” box, B -type was 16” and so forth. Truss with tracks built into them, their own swing wing, and curved truss are also types they offer to this day. I do not know if Huntley Christie ever bought any truss someone else made.

An Englishman named Ronan Willson got the gig for the Flick of the Switch tour. That band wanted a big lighting system, and their PM Jake Berry insisted that Ronan use pre rigged truss. Someone fronted Ronan 300,000 pounds to build a system. With that, he went to his friends (at the time) at Thomas and laid out his plans. After a single prototype, Willson, Dizzy Gosnell and Chris Cronin from Thomas came up with the final truss design and hired Thomas to build them for him. From the moment Ronan got the gig, he and Dizzy had 8 weeks to fabricate what had been drawn on paper and get it in sea containers. Eventually Willson signed a deal with Thomas where they paid him one pound for every piece of PRT they sold. Iron Maiden started buying their own gear in PRT in 1983 that Meteorlites looked after as well.

Now this led to the creation of the first Pods of lights I saw, though I’m sure there were others. The first pods I remember seeing were made from three sections of this PRT. They were placed sideways and held together with two ratchet straps and a bar with half couplers. You can find plots from old Maiden tours with 20 or so of these pods, which were basically 36 par cans in a square.

Showlites built these pods that contained a bunch of silver pars and could be hung from a straight truss. They had a foot board across the bottom if I recall, so the techs could walk across it to focus the lights. I remember seeing these giant pods hung across rigs for Billy Joel and David Lee Roth. I did a Night Ranger tour with Morpheus Lights that designed these 8’ tall pods with pars that rolled in to the venue upright. They were too heavy to lift manually. I had five of these pods that were hung from a Morpheus box truss. We got out on tour and realized the lengths for the multi-cables weren’t long enough to go up on the box truss and drop down to the pods. So for two days we ran the cable right from the dimmers across all of the pods, which really sucked to tie on with tie line. That is until we collected enough of the bras the teenaged girls would throw up on stage, then used them as cable fasteners. It was a colorful addition that I think most stagehands got a kick out of.

R.A. Roth designed these awesome open faced pods in triangular and hexagon shapes. I hung everything from moles to movers to strobes off those things. Last I saw they had a few of these hanging in the House of Blues in Vegas. Salvaged last minute out of a PRG dumpster I was told.

Sometime in my career I was told by a Stage Rigging employee that it was a known fact that triangle truss was stronger than box truss. Unfortunately I can verify this by a gig I did in Brazil with Paul Simon 30 years ago. The system called for some straight trusses with Varilites and par bars on them. As the trusses came out of the truck that morning in Sao Paulo, rigger Lyle Centola would inspect them for cracked welds, bent rails etc.. He tossed about 1/3 of them away and refused to use them. So Sergio the lighting owner got the shop to bring down some 20” triangle truss he owned.

Now 30 years ago motorized chain hoists were not readily available in Sao Paulo so everyone used hand pull chain lifts, like the kind a garage might use to lift an engine block out of a vehicle. The problem was that once you were ready to raise the truss the locals would have a race, pulling as fast as they could on their chains to get their side of the three motors up to trim. This would take about 20 minutes per truss, as we constantly had to yell “Stop” and get some teams to pull a chain to catch up and level out the truss. You could count out the chain pulls, but it was almost always a race.

We do the gig and commence load out. While they are clearing the stage of set carts I go out to Front of House to strike the consoles. As I’m out there I see the locals decide it’s time to lower the two upstage trusses. One box, one triangle. Once again the great chain race commences, but there’s nobody on stage directing them but the local lighting crew boss. As I look up the only hoist with any weight on it is the center point on both trusses. As I run back towards the stage I am too late. With an ear piercing sound of metal twisting the box truss collapses on itself, flattening out. The triangle truss held and we quickly lowered the center point to avoid that from breaking. As a side not, the box truss contained a bunch of Varilites that had J-hooks that attached with a quarter turn. With the truss collapsed around the hooks we could not remove the lights. Thankfully the carpenter had a Sawzall and Varilite had a shop with more hooks in Rio, the next town on the tour. We cut the lights off the folded truss

In 1983 I was sent out to fill in for someone on a Rush tour. I still recall that first day as I walked into the arena and looked up at a 48’ x 40’ lighting rig that was full of lights. There was not a hole left where Howard Ungerleider could hang another conventional fixture and still focus it. That rig was made from tons of truss with pipes, truss circles and ladder truss cheseboro’d everywhere. Back then it was really cool. Today it might be considered a flying junkyard. The lighting itself looked amazing, but this rig was a bear for six techs to put up and focus. So for the next tour Bob See had decided they needed to come up with a system of pods that could fasten together like truss. Thus was born the RDLM, the Rapid Deployment lighting Module. It was first used on a Triumph tour.

The problem was these things had a lot of bits that needed to be utilized to get a rig up. Mother grids, spanset placement, dual sized bolts and ratchet straps all made for a really long day and in the end, the words Rapid Deployment were far from realistic. The pods only held 5 pars by 5 pars if you wished to focus them – since Bob never bought proper 6-lamp bars at this time it worked for what he had (unistrut).

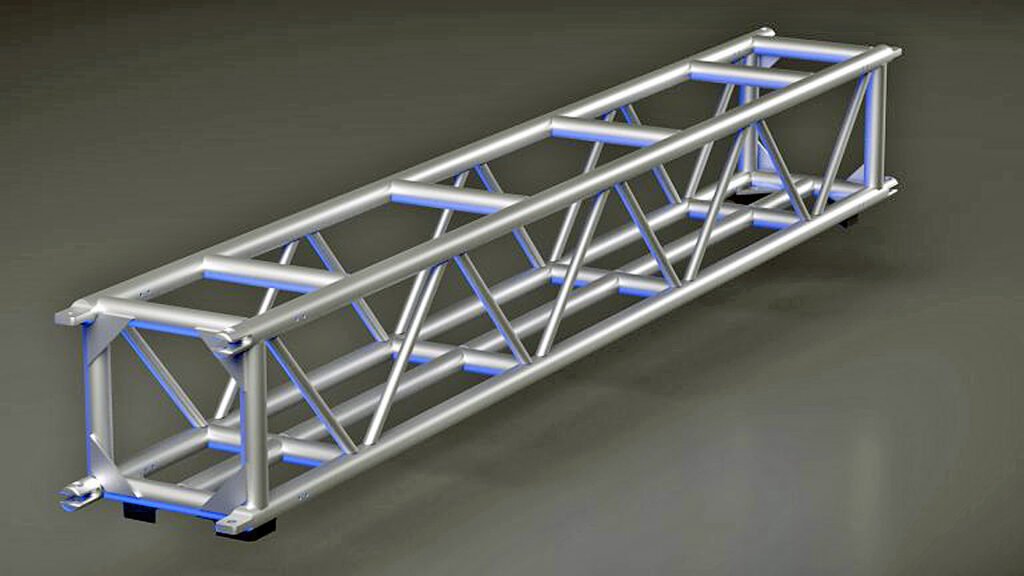

The image included with this article is of RDLMs in use from that Triumph tour. It was submitted to me by master electrician Scott Maskin. See Factor used 1k dimmers on this tour, which enabled the electrician to hot patch the dimmers to spell certain words that let the band know how he felt about their catering choice that day. Or perhaps the band itself.

Now with the additions of touring pods, many tours started rigging a mother grid first. This is a rig consisting of just large truss with many other smaller hoists permanently living in that truss. It needed to be bigger and beefier, Companies started making 30” tall box truss on wheels. I did a tour where the riggers simply hung 9 two tons (maybe not so simply), and that lifted up a 40x 60’ grid of super truss that held 40 lighter weight chain hoists.

Self-climbing truss roofs became a thing as well. Truss manufacturers started offering up beefed up models of 12 and 20” truss with diagonals placed in multiple directions inside the truss. Four pole roofs required this type for their upright truss.

The more pars you have, the more time you need to focus. It could take 2-4 hours to focus a Rush lighting rig. Two – if the road crew did it, four if the local IATSE went up. The locals weren’t used to climbing on these pods. The crew tried to wrench the lights in the pod tight to avoid much focus time. This reminds me of a rumor I’ve heard about Bill MacManus who owned his own lighting company in Philadelphia. This story has been verified and vilified by his former employees, I don’t know if it’s true, but it makes for a great tall tale. McManus was the LD as well as lighting vendor for Kiss at some point in their early career. Rumor has it that the LD decided he could save time if he lowered the rig down after rehearsals and tack welded all the pars to their yokes and the yokes to their unistrut bars, so the LD would never ever have to focus the pars for the rest of the tour. Seemingly brilliant concept. Until the first gig with a low trim. I don’t have to tell you the rest.

Automated Lights brought around a need for new truss. One that could hold moving lights instead of pars. Tait Towers had the first swing wing truss I ever saw, a type of truss where the sides swung upwards and pinned in place. The beauty of this truss is once the sides were up you did not have to drop down any bars and the pars could focus in any direction.

In the late 80’s Morpheus Lights had a guy named Danny English that ran the shop. Danny worked with the Grateful Dead often and for every leg, their designer would need custom truss blocks welded for all these weird angles she incorporated into her rig. None of these were ever OSHA regulated nor structurally engineered and Danny sure wasn’t legally one, but he was incredibly smart. He had a knack for designing all kinds of cool stuff that wasn’t over engineered and just made for a faster load in. Morpheus developed the Pan Command system (think of a six lamp bar of moving lights) with two bars fitting in each 30” wide x 8’ long section of swing wing truss. The nuts were built into one end of the truss and the 6” long bolts lived in a little holes at the end of the truss, so you never lost a bolt or went looking for an ammo box to lug around the stage. The sides swung up, held in place with some side arms you pinned in place. The bars of lights manually slid apart so they didn’t bump when moving. Two removable legs with wheels would have to be removed once the trust was lifted.

Even with a dozen moving lights inside it this Morpheus truss was hand liftable, to be stacked. The easiest way to stack it was to leave a single motor rigged and use some spansets to stack them, but that was not always available, especially at load in. So the company furnished each show with these ten foot long steel rods. The rods would slide through these holes cut in the removable wheels and four (sometimes 8) people could lift and jerk the truss up into position while another team rolled another piece under it. It was quite effective, once the stagehands quit moaning.

It took about ten years for other companies to adapt this swing wing technology. But they over engineered it so much it negated much of the time the Morpheus model saved us. The new swing wing was also twice a heavy as the Morpheus stuff. It had to be stacked with a hoist.

It did seriously save truck space though.

Come 1994 Varilite debuted their Autotruss. These were 8’ sections of box truss with an open bottom. The sides and top were beefy as hell. The truss could hold 3 VL2C’s or any fixture you wanted. What was different about this truss is that it used internal motors to lift and lower the Varilites out of the truss via a CM pickle (hand control). The anticipated value of this product was that users could just roll the Autotruss into a semi and lift it up on end. The concept behind the product was fairly ingenuous. But in the end it took more time than hanging an empty truss and slapping three lights on it. The only benefit was that is saved truck space.

We used this truss on a Phil Collins tour which made sense since he still had a stake in the company back around 1994. We would have to lift the truss up off the ground a couple feet, then have everyone watch the lights as they lowered down to make sure some cables were not caught and broken. The drive on this truss insured that the lights were lowered very slowly, but the torque would easily rip a socopex connector right off. So we had to lift the truss, lower the lights, then stand on the rails of the truss to plug in all the cables.

In order to protect the Varilite yokes of the fixtures from breaking off in transit when stood on end, VL had these plastic and metal trays made with cutouts of the fixtures. They would have to be applied to the truss after the lights were sucked up into it. They were no fun. In the end I believe Varilite wanted an exorbitant amount to rent these on a tour. I don’t know where they went after that tour, but a recycle bin is my guess as I never saw them again.

I was doing a lot of work with Upstaging around the time they invented the HUD truss. Maybe it stood for Handy Utility something, but everyone knew John Huddleston was behind the idea. It’s safe to say that this truss revolutionized touring as it came in 5’, 8’ and 10’ sections and you could hang any light with their own clamps inside it. A mere 14” tall by 24” wide, they could be stacked and fit four across in a semi. With a 14” side wall, most moving lights could shoot out without having to be lowered. Tyler Truss worked with Upstaging on quite a few revisions until they got it down. Then Upstaging bought 100’s of these before anyone else.

Eventually Tyler started selling this truss model to other companies. There’s a story going around that a lighting vendor wanted to buy a whole bunch of the truss, but damn if they were going to call it HUD truss. So Tyler renamed it GT truss, which stood for Green and Tyler. It wasn’t long before companies such as PRG and Christie came up with their own versions of this model with clever adaptions.

The only new truss I can recall seeing in the last ten years are the models designed to hold video. This is basically a 20 inch truss with an extra center rail welded in the bottom. I wonder why there haven’t been new models designed, maybe we don’t need anymore. I’m sure I missed quite a few models here, but as I said before, this is just one man’s experience spanning 40 years of truss.

Lastly, I have always wondered why everyone makes “20 inch box truss” that is actually 20.5 inches wide. I always wondered if it was a design flaw on the first one and everyone just copied it or if there was a logical reason for this odd width. One of the many mysteries hidden in truss.

No responses yet