By the late ‘70s, many of concert lighting’s pioneers, still young, could look back on the past five years with satisfaction. Popular music had become a multi-billion dollar business. Live concerts the nation’s best-attended performances. And, (David Lee Roth saying, “If all the world’s a stage, I want better lighting!”) made a new generation of growing businesses.

David is also credited with: “Here today, gone later this afternoon”. Few anticipated the turbulence of the next few years.

Most of the biggest names in American concert lighting in the mid-70s, later dubbed “dinosaurs”, would be done-in, by a perfect storm of subtle shifts in concert economics and some not-so-new “technology”.

And this, even before the threat of the automated lighting “asteroid” (an image attributed to Fred Foster) loomed overhead.

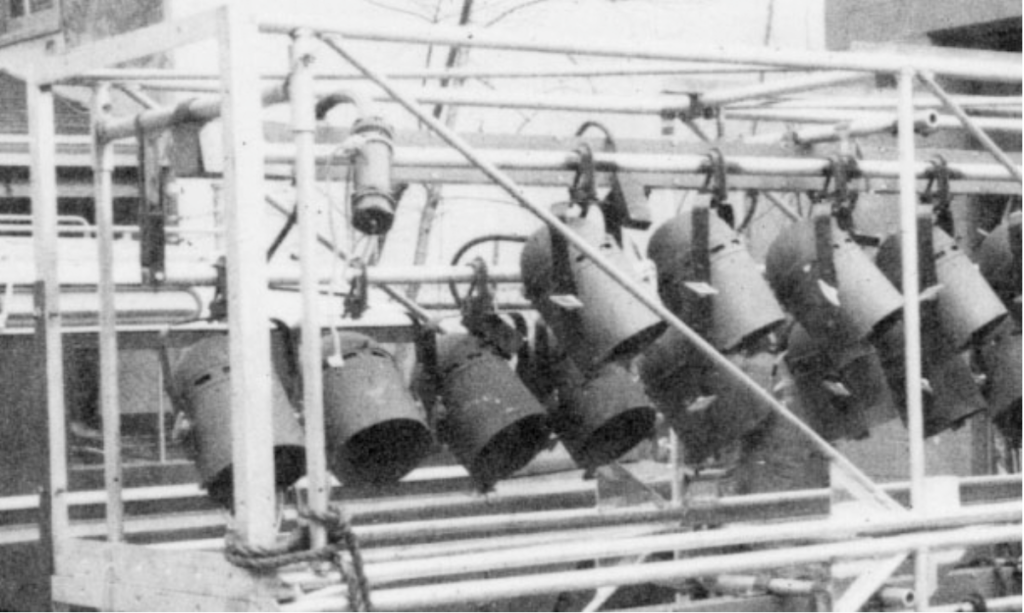

A detail of the Stonesʼ 1972 truss

They had started small. When I met Bob See, his lighting business fit in an unlit storefront, across the street from the Fillmore East. His next “shop” was a few blocks north, but still small enough that marking their new triangle truss for an upcoming Deep Purple tour of Japan had to be done on the sidewalk outside.

Systems grew rapidly in both size and number. Sometimes larger for reasons other than aesthetics. The LD for one major act was fired when he didn’t agree that two hundred fixtures were now necessary.

Many of the tour lighting shops of the early 70s used “box” trusses.

Many plugged-up both lamps and dimmers one circuit at a time. A 250-fixture Aerosmith show had 250 runs of 16/3 SJ cable – and a guy whose job was just plugging up racks. When he was done, the cable mass on the floor was a foot deep. Not the most efficient of systems, and one which the shop’s owner would later defend for its simplicity, because he had to hire “monkeys” (who he compensated partly in cash and partly in coke).

But, in the realities of the time, ‘70s US tour lighting (much like car making) was all-American, often inefficient – and, still, doing just fine.

Over there

At first, UK tour companies imported American gear: Vermette lifts, Altman PAR cans. But it wasn’t long before they started “rolling their own”.

Their new hardware reflected a fresh start, and their different conditions and opportunities. European trucks were smaller; venues could be more challenging; and local crews more..variable.

That meant more of the setup might have to be done by the road crew; requiring a more labor-efficient system.

It started with the PAR can itself.

The Altman can, which had grown out of a short-barrel Four Star design, was made of sheet steel.

Light & Sound Design had their own PAR64s spun out of thin aluminum at a local metalwork shop run by Graham Thomas. Eventually they fell out with each other, and LSD took PAR can spinning in-house, while Graham produced his own variant, first sold as OEM to various UK shops, then under the “James Thomas Engineering” brand.

In its early version, the Altman can had easily bent gel clips, and a front barrel that could be deformed in handing; making both gel frame insertion

and retention difficult. UK PAR cans were spun with a front stiffening ridge; had robust gel clips including leaf springs to grip the gel frame (which, being octagonal in shape, helped the fixture pack and focus better).

Being much lighter, spun aluminum cans made a 6-lamp bar a reasonable lift, either loose or within a “pre-rig” truss section.

And the hollow bar offered both a raceway for wiring and a mounting point for a 6-circuit multi-connector.

The embrace of multi-connectors with one circuit per fixture would distinguish the next generation of concert lighting systems on both sides of the Atlantic.

Multi-connector use wasn’t new. The Stones ‘72 tour, Bill Graham’s own production company, and a few “A-list” U.S. shops had used Pyle-National’s Star-Line, the only domestic power-level connector big enough and rugged enough for touring. Developed for military and aerospace, it also had a price tag to match.

But many American “first generation” tour lighting systems used either bundled single-circuit cables or multi-circuit SO “fanned out” into pin or twistlock connector pigtails at either end.

The Brits found an affordable connector – the Socopex – and a compact and flexible multicable, Lapp Olflex.

With a circuit dedicated to each fixture, all load-patching could be moved to the dimmers, and, “over there”, higher voltages meant smaller wire gauges and allowed using connectors with pins too small for 120v systems.

In the States, the circuit-per-lamp approach emerged in 1976, in a small system from Capron Lighting in Boston. Using #16/37 cable of a reduced size and weight (SDN or NVN) for either twelve fixtures/circuits as 3-wire or sixteen fixtures with shared ground, it became a defacto standard among progressive U.S. shops.

American shops were limited to dimmers developed for general theatrical use, typically in 2kw or larger sizes. That required twoferring 1kw PARs at

the position for efficient use of #12 gauge cable, as well as load-patching

at the dimmers.

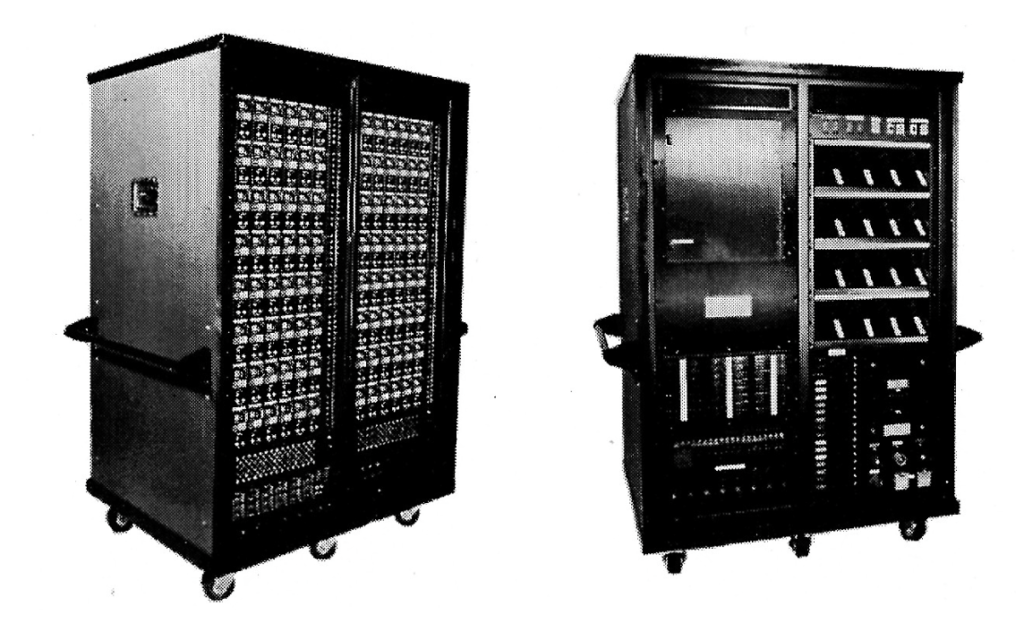

The British built their own 10A dimmers in high-density touring racks. The Americans got theirs by way of a start-up called Lighting Methods.

Concert lighting didnʼt get the best dimming solutions until it built its own

On the left: the UK solution, represented by 6-circuit Olflex cable terminated in Socopex or Litton/Veam connectors and with a dimmer rack by Avolites or Alderham. Load patching with jumpers in the top was necessary because tour shops preferred 120v PAR “bottles” over those 240 versions available.

On the right, the US: Dimmers by Lighting Methods, supplying #16/37 SDN

multi terminated in Pyle-Nationals. Dimmer-per-circuit-per-lamp eliminated the need for load-patching 120v 1000w loads.

Cross-currents

By the late ‘70s, concert lighting’s dramatic improvements in setup efficiency had attracted the attention of those serving more traditional markets like location television – and bus-and-truck dance and theatre, where the limits on what could be accomplished in an 8-hour load-in could restrict a touring plot to about a third of the original New York production’s.

In the U.S. lighting market of the period, different markets had very distinct vendors, manufacturers, and gear.

Visualize a triangle.

- At one corner you had concert lighting. PAR64s, truss, chain motors, 1kw multi-cable and dimmers; few lekos and no film/TV gear

- At the second, theatre/opera/dance. Lekos, few PARs, no truss or motors, no multi, no film/TV gear

- At the third, film and TV. Fresnels, no truss, no multi, no dimmers.

When a young New York hire shop serving dance and Off-Broadway, Production Arts, decided to adopt concert techniques, the result was a hybrid. Side towers were essentially vertical “box” trusses. Overhead electrics were Unistrut lamp bars served with “soft” multi-cable breakouts.

In search of growth and diversification, tour lighting shops were happy to offer their services to other markets. But the very specialization of their systems was a barrier. PAR cans had some utility in some kinds of event and television lighting, but more lekos and film/TV grade fresnels were needed.

Their bigger problem proved to be in cabling and dimming. Built around 1kw circuits and full usage at a lamp bar or truss section, they weren’t suited to accommodating 2kw fresnels, traditional theatrical hangs, or its mix of smaller fixture wattages, often combined at the position into 2kw circuits.

That meant, for those with 1kw Soco, buying 2kw cable (the Soco’s pins were already 2kw rated). For those with Litton/Veam or Pyle-terminated 1kw cable, it mean an even larger investment.

Multi-cable use also required 2kw dimmer racks with onboard load-patch to compensate for the often lower utilization of multi-cable capacity, both in actual circuit wattage and the number of circuits in a multi used.

Production Arts chose a “ground up” solution from Lighting Methods, using a rack design based on concert techniques, a 2kw drawer-type dimmer, and a load-patch using .25” quick connects.

The design of SCR dimmers themselves had evolved alongside tour lighting systems.

Or, more accurately (as summarized in the accompanying “A Brief Walk through Dimming”), evolved from large wattages (6kw and 7kw), necessary because of the cost and fragility of early SCRs themselves, towards a convenient 2kw size.

One that, in permanent installs, given one dimmer hard-wired to each circuit and a softpatch, would eliminate the cost and labor of load-patching – albeit while requiring hundreds of such dimmers.

So, while concert lighting was building its own 10A dimmers for touring racks, established theatrical manufacturers were value-engineering the 2kw size.

That was led by Entertec, for a succession of clients, converging with the ETC Sensor dimmer in essentially the same rack design as PA’s RD2000.

After an unfortunate detour into #12/37 multi-cable, high density Sensor touring racks for all markets assumed the form they have to this day: around

a cross-market standard of 6-circuit 2k “Soco” cable, having its roots in 1970s Brit rock.

Convergence and Diffusion

The hardware used in lighting and the inventory of many shops began to converge towards the center of the Concert/Theatrical/Film&TV triangle, with gear that had formerly been largely the province of only one of them.

Both theatrical and concert shops discovered that the rate-of-return for film & TV stuff was very attractive; and more designers who had come out of concert lighting began doing television, including “music for television”, and calling upon not only concert techniques but concert vendors to do it.

As folks who attended concerts began running business meetings, their visual standards were increasingly shaped by what they had seen on tour, and the Fortune 500 business meeting would use a similar “vocabulary”.

This wider range of fixture types and applications outside the concert market also required more versatile fixture support. Shipping fixtures individually in lamp crates and hanging them on generic rectangular truss types like “12×12” and 20.5 became typical, for several reasons.

Another trend was the appearance of companies offering truss (and other system components) for sale, where once tour shops had built them in-house, contracted them from welders, (or bought antenna mast). The wide variety

of designs seen in the experimentation of the early ‘70s were largely replaced by a few generic designs produced by many manufacturers that were interchangeable.

Meanwhile, back in concert touring…

Chain motors were adopted from circus rigging and embraced early in arena touring for lighting. Flown PA came later.

By the late 70s, a few progressive American tour lighting shops had evolved to contemporary UK standards. Many of the earliest ones had chosen to simply soldier on with their much less labor-efficient early-70s systems.

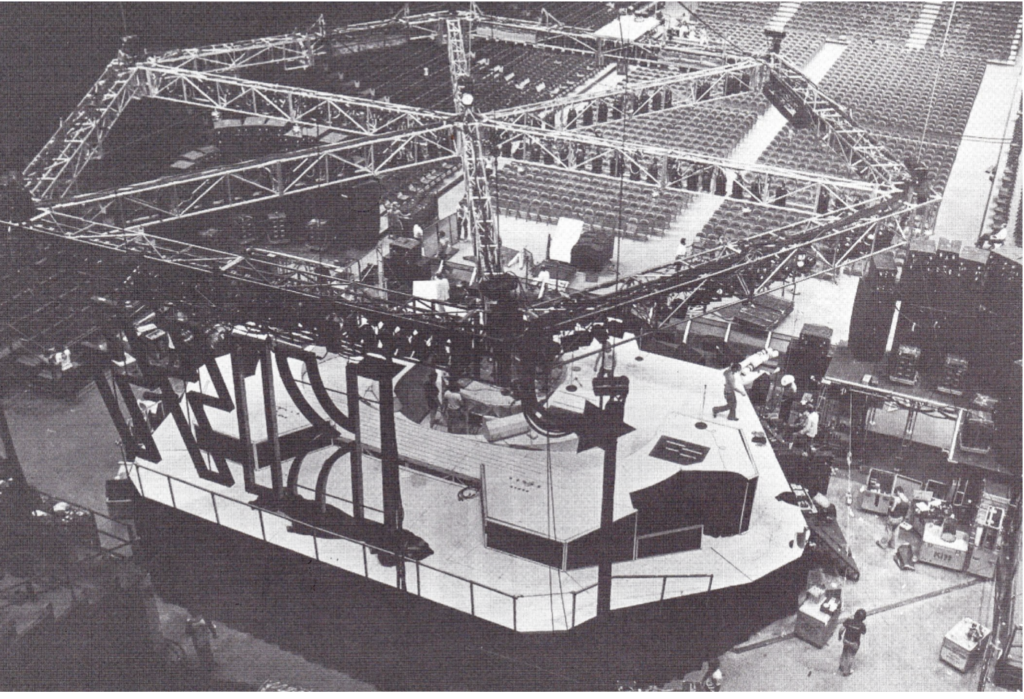

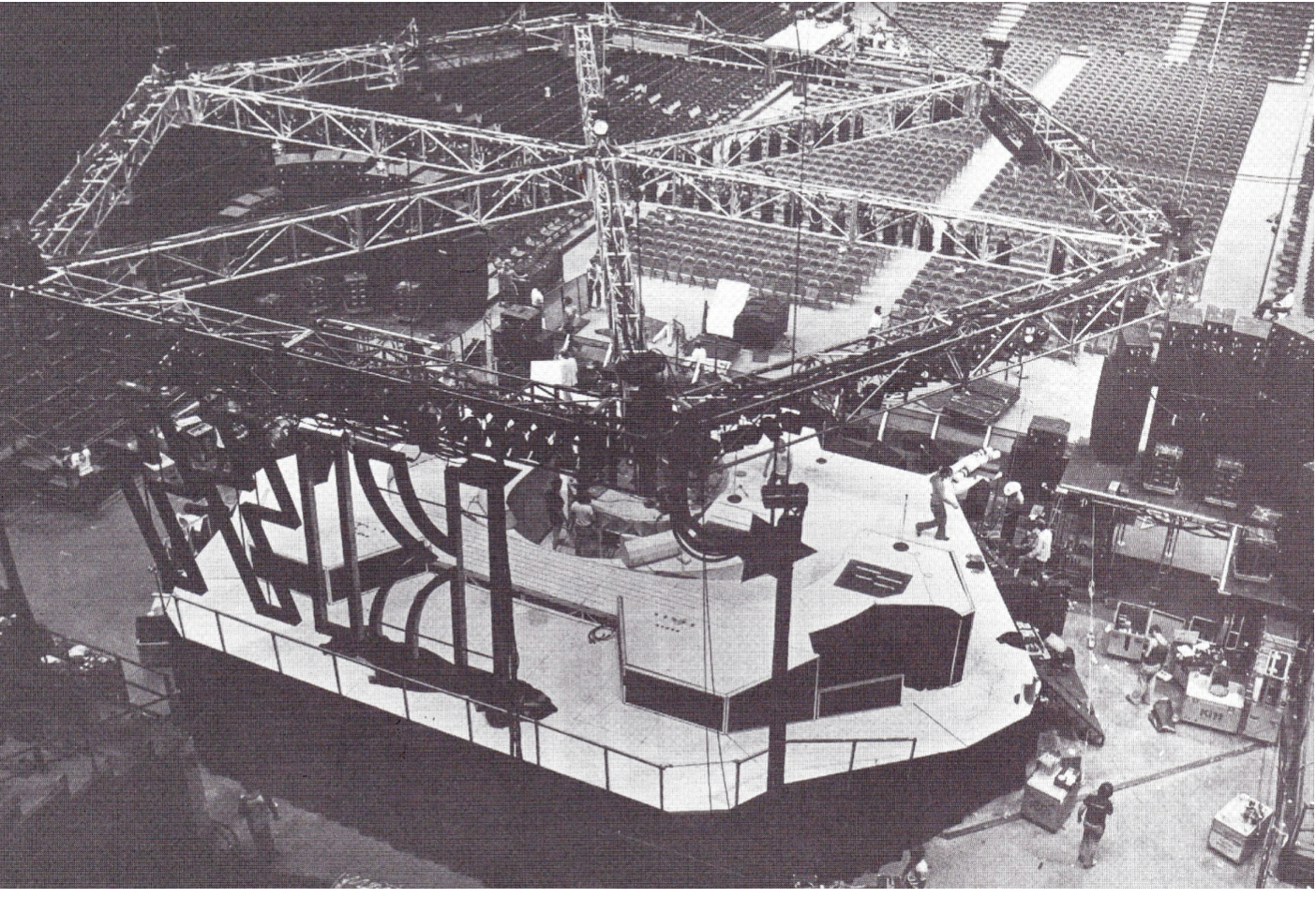

On the rock lighting landscape, the most important player was Dallas- based Showco. They’d innovated and standardized early, driving the market with a “one stop shop” approach to tour production, which forced sound companies to partner with lighting companies or start their own. But, behind the scenes, a subtle shift in how bands were paid would set up Showco – and a number of early-70’s “names” for a fall.

In the world of early-70s rock, acts were paid on a flat fee or tickets sold basis, but the promoter ate venue expenses, so an inefficient lighting system was no disadvantage – especially if the “monkeys” came cheap and money hadn’t been spent on more modern construction.

The Rolling Stones, in the interests of maximizing their take, pioneered the “90/10 split”. Concert expenses were subtracted from gross ticket sales and the gross profit split between promoter and band. Now, the act was paying 90 cents of every dollar going to stage crew and teamster labor. Accountants did the settlements and managers put tour services out to bid.

Then came the first Arab oil shock. Gas lines. The cost of petroleum products used by the fan to drive to the concert – and the record company to press the LP – shot up. Record companies cut the subsidies that had allowed mid-market acts to take larger production on the road for the years before they had built a fan base big enough to reach profitability at the arena box office.

Suddenly, too many lighting systems were chasing too few acts. And many of the hottest acts on the road were Brits – bringing the latest Brit gear with them.

Many of the biggest names in ‘70s concert lighting were now dinosaurs unsuited to the new climate. And lacking the cash flow to finance a belated upgrade to their systems. Most didn’t survive.

Showco was one. From being a pioneer and driver of the market, Showco was reduced to advertising a fire sale of their lighting equipment. After failed efforts at diversification (trucking, laser shows, disco equipment, sound installs) the now King Dinosaur was reduced to a large, mediocre sound company.

In a last Hail Mary effort, a PAR can color changer was designed.

That was an ironic way to end the ‘70s. In ’73 Chip Monck had sought a color changer to make the sixty PAR cans of his ’72 rig look like 300.

In fact, through improvements in efficiency, it was now possible to carry all 300.

But Showco’s last hope in lighting was that a color changer could reverse the equation, saving their PAR-based business.

No responses yet